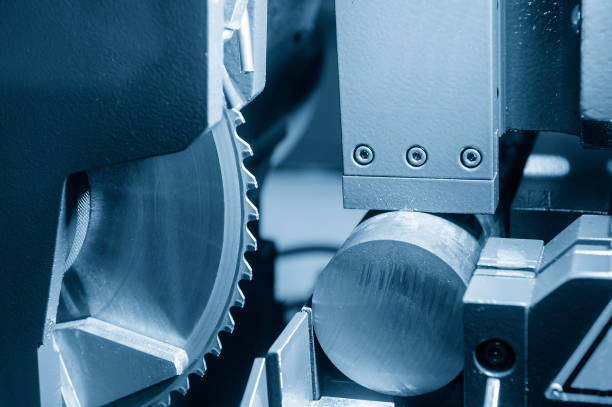

Tungsten Carbide Tipped Cold Saw blades are specifically designed circular saw cutters used in Circular Saw Machines for cutting metals. These blades are designed with tungsten carbide tips attached to the teeth, providing durability and efficiency in cutting through metal materials.

Outside Diameter | Body Thickness | Inside Diameter | Number of Teeth (Z) |

250 | 2.0 | 32(40) | 60, 72, 80, 100 |

285 | 2.0 | 32(40) | 60, 72, 80, 100 |

315 | 2.25 | 40(50) | 60, 72, 80, 100 |

360 | 2.25 | 40(50) | 60, 72, 80, 100 |

420 | 2.25 | 50 | 60, 72, 80, 100 |

460 | 2.25 | 40(50) | 54, 60, 72, 80 |

Here are some key characteristics of TCT circular saw blades :-

TCT cold saw blades have small pieces of tungsten carbide that are brazed or welded onto the teeth of the blade. Tungsten Carbide is extremely hard and heat-resistant, making it ideal for cutting tough materials like steel, aluminum, and other metals. The combination of the blade material and the tungsten carbide tips allows for faster cutting rates while maintaining cutting precision.

- Compared to traditional high-speed steel (HSS) blades, TCT blades can withstand higher cutting speeds .

- Due to tungsten carbide tips these cutters have excellent wear resistance. This results in longer blade life and fewer blade changes, which can improve productivity and reduce downtime.

- These Cutters provide clean and precise cuts with minimal rough edges or burr

- Using circular saw cutters provides great accuracy and tight tolerances.

- These blades can cut through various metals, including ferrous and non-ferrous materials like steel, aluminum, brass, copper, and more.

Applicability by Material

- Stainless Steel

- Structural Steels

- Bundled small diameter material s

- Alloy Steel

- Non-ferrous metals

- Hot work tool Steel

- Tool Steel

Machine Compatibility

- ITL

- INDOTECH

- AMADA

- EXACUT

- MEBA

- EVERISING

- CAPSTONE

Authorized Circular Saw distributor for-